Crusher Hammer

– Hammer Crusher Wear Parts

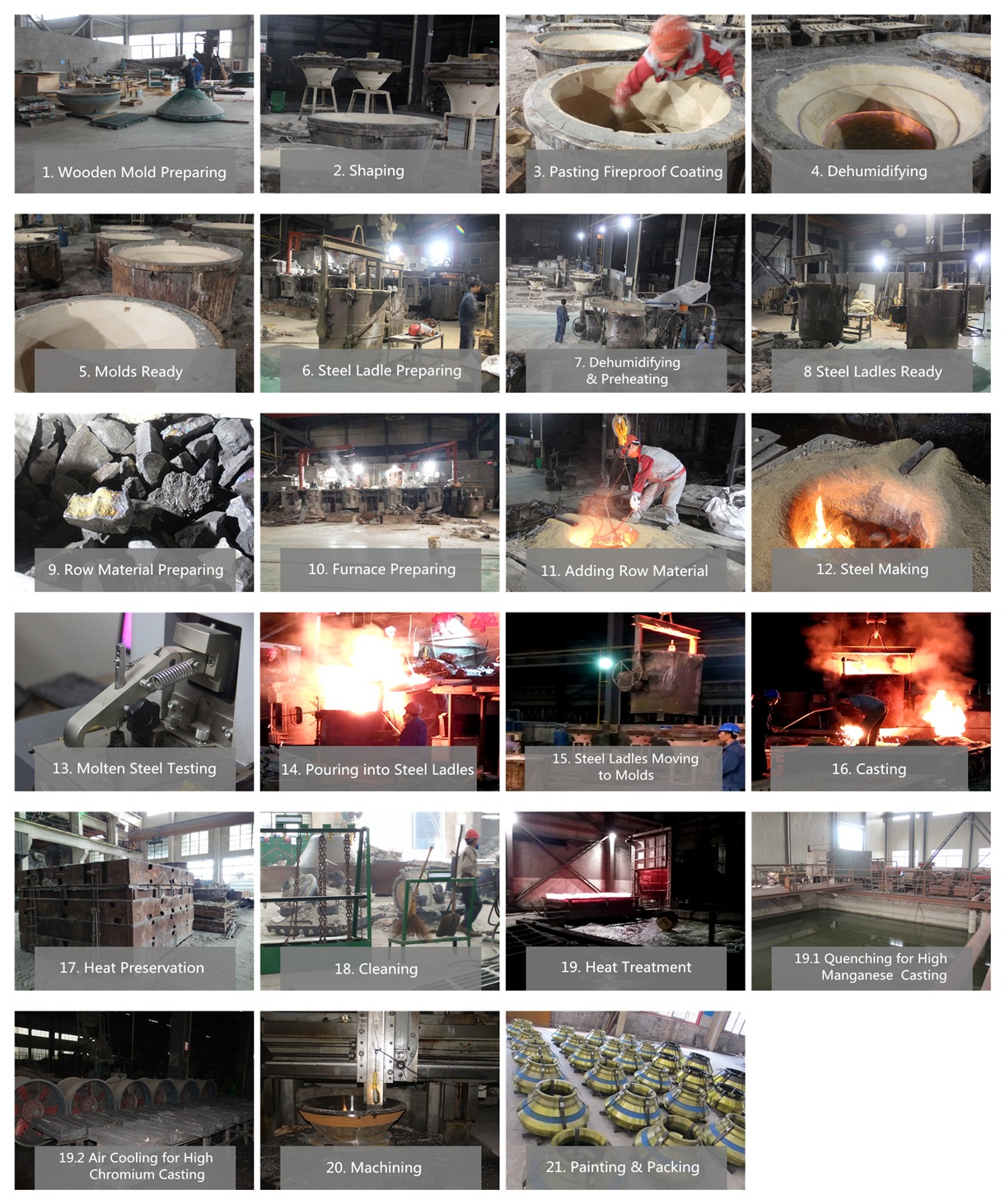

Crusher Hammer such as clinker crusher hammer and raw material hammer are the core parts of Hammer Crusher. Our hammer crusher parts: crusher hammers use refining, vacuum casting, directional solid and etc technicals to increase the grain refinement and make the hammer performance achieve the best performance.

Hammer’s hardness is the most essential factor in determining hammer life so the hammer head must be extremely hard and resistant to wear. Our Hammer can reach to HRC58~HRC63 with a service life 50~100% longer than those made of traditional high chromium iron.

| Name | Crusher Hammer, high wearable hammers |

| Material | Cr20Mn2,Cr26Mn2 |

| Control | Spectrometer chemical analysis and control while producing |

| Molding Process | Water-glass sand casting or lost form casting |

| Melting facility | Medium frequency electric furnace |

| Heat Treatment | Anneal, quenching, tempering |

| Quality Guarantee | None |

| Testing | Hardness, flaw detector test |

| Certificate | ISO9001~2008 Passed; BUREAU VERITAS |

| Application | Cement firms, coal fired power plant, mining firms, metallurgy, quarry firms |

| Packaging Details | As the clients’requirement |

| Delivery Time | 20~30 days after payment |

High Chrome Casting Material Chemical Composition(%)

| Designation | Hardness of work site(HRC) | Ak/cm | Working life (Other Products) | |

| high manganese hammerhead | Cast Iron Mill Liners | |||

| Cr15 | 50-60 | ≥30 | ≥1.5 | ≥5 |

| Cr20 | 58-62 | ≥30 | ≥2 | ≥5 |

| Cr26 | 60-65 | ≥30 | ≥2–3 | ≥5 |

![]() Mechanical property test report-Willing (Shanghai) Industrial Co.,Ltd

Mechanical property test report-Willing (Shanghai) Industrial Co.,Ltd

![]() Metallographic inspection report-Willing (Shanghai) Industrial Co.,Ltd

Metallographic inspection report-Willing (Shanghai) Industrial Co.,Ltd

![]() The spectrum test report-Willing (Shanghai) Industrial Co.,Ltd

The spectrum test report-Willing (Shanghai) Industrial Co.,Ltd

|

|