Project Description

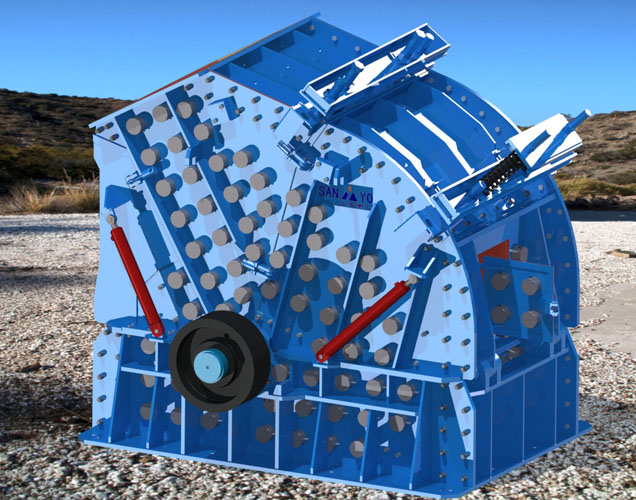

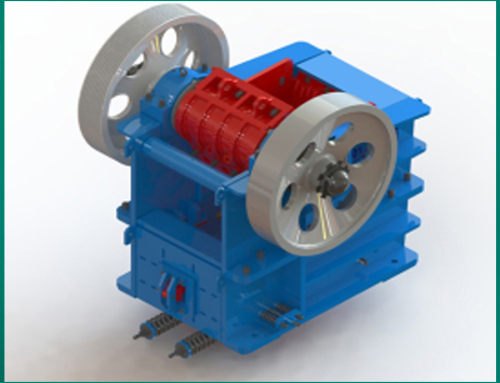

- The Hydraulic Impact Crusher is designed with a multi crushing cavity.

- Built with a newly designed wear-resistant hammer and gear impact liner made from high quality chromium to reduce wear.

- Able to produce bulk amounts of evenly sized cubic shaped material.

- The Hydraulic Impact Crusher is able to discharge bulk amounts of cubic shaped material.

- Low and wide feeding inlet opening is convenient for feeding large material and assembly of line.

- Easy to operate and repair and can be used in different crushing operations.

- Easy adjustment process which simplifies process.

- An even-shaped plate design discharges smaller sized, cubic shaped, and crackfree material.

| Model | Feeding opening size (mm) | Max feeding size (mm) | Capacity (t/h) | Power (kw) | Weight (kg) | Dimensions (mm) |

| HM130 | 1350×500 | 300 | 120-200 | 132-200 | 17465 | 3010×2450×2750 |

| HM150 | 1530×500 | 350 | 200-300 | 200 | 36230 | 3200×2630×3080 |

| Electrical requirement | 380 to 420V, AC(50/60Hz) or according to local standard | |||||

| Temperature range | -50℃ to 70℃ | |||||

| Adjustment mode | Hydraulic | |||||

| Opening cover way | Hydraulic system | |||||

| Raw material water content | ≤20% | |||||

| Design Type | Normal & Euro Type | |||||

| Electric Control system | ABB & Schneider, PLC | |||||

| Crush method | Stone to stone crushing | |||||

| Standard | Euro standard | |||||