Project Description

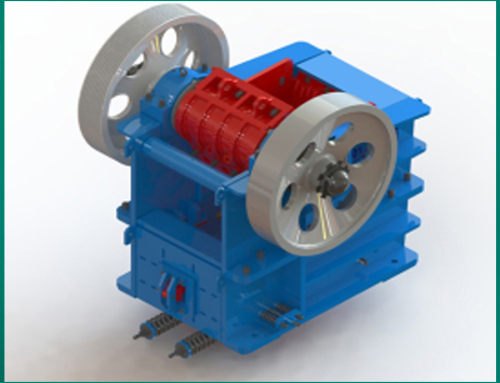

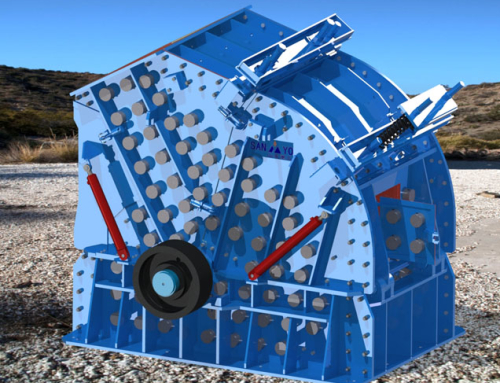

HPT series multi cylinder hydraulic cone crusher is widely used in metallurgy, Mining, cement, chemical and other industrial sectors, as well as the highway construction, water conservancy projects, construction debris, sand making, etc, The cone crusher , suitable for crushing hard and above medium hardness of all kinds of ores and rocks, is the most ideal equipment of large Shi Liao chang and mining crushing.

- Structure upgrade and higher efficiency

At the basis of structure of unique spindle fixation and eccentric sleeve around the main shaft, the transmission rotation parts and the lubrication seal of equipment were further optimized. The carrying capacity of equipment is strong and the installed power reaches the biggest at the same type of industry with small volume, high efficiency and low noise. - Full hydraulic control with accurate and reliable

From the insurance clearance to adjust and lock,the equipment was used full hydraulic operation, more stable and reliable, and easy to operate. With rich experience in practice, the hydraulic system has a better structure and more accurate adjustment and control. It can automatically protect the reaction rate faster, but also can realize the full automation operation. - Hydraulic lubrication integration and automation of equipment control

Equipped with integration hydraulic lubrication system and centralized automatic intelligent control system,it can save the cost of hydraulic lubrication input ,but also can monitor equipment running state real-time. Further optimization of the control system and more stable and reliable system, guarantee the safe and stable operation of equipment. At the same time, the equipment operation is more worry and effort. - Laminated crushing and good product shape

Use the principle of laminated crushing to crush the material and improve the laminating crushing efficiency through the optimization of equipment and the chamber.High crushing efficiency, low wearing parts wear,cube shape of finished product, high content of fine grain size, improve product quality, reduce the production cost of the equipment and the whole system. - Multi cavity conversion and one machine with more purposes

Configuration of the multi medium crushing and fine crushing cavities, and only replacing the corresponding liner plated of cavity and a few parts, it can be converted in the cavity type. Combining with the principle of laminated crushing, it’s better to meet the process requirements of medium crushing and fine crushing and realized one machine with more purposes. The mantle and concave were made by the high manganese steel. Due to the crushing cavity changes and the protection of material layer in the process of laminated crushing, the wear is reduced and the general life can be increased from 35% to 82% compared to the old structure of cone crusher.

| Model | Chamber | Tight side feed opening size(mm) | Min discharge opening(mm) | Producing capacity(t/h) | Main Motor Power(kw) |

| HPT100 | C1(Extra coarse) | 140 | 19 | 50-140 | 90 |

| C2(Coarse) | 100 | 13 | |||

| M(medium) | 70 | 9 | |||

| F1(Fine) | 50 | 9 | |||

| F2(Superfine) | 20 | 6 | |||

| HPT200 | C2(Coarse) | 185 | 19 | 90-250 | 160 |

| M(medium) | 125 | 16 | |||

| F1(Fine) | 95 | 13 | |||

| F2(Superfine) | 75 | 10 | |||

| HPT300 | C1(Extra coarse) | 230 | 25 | 110-440 | 250 |

| C2(Coarse) | 210 | 19 | |||

| M(medium) | 150 | 16 | |||

| F1(Fine) | 105 | 13 | |||

| F2(Superfine) | 80 | 10 | |||

| HPT400 | C1(Extra coarse) | 295 | 30 | 135-630 | 315 |

| C2(Coarse) | 251 | 25 | |||

| M(medium) | 196 | 20 | |||

| F1(Fine) | 110 | 13 | |||

| F2(Superfine) | 90 | 10 | |||

| HPT500 | C1(Extra coarse) | 330 | 38 | 220-790 | 400 |

| C2(Coarse) | 290 | 30 | |||

| M(medium) | 210 | 22 | |||

| F1(Fine) | 135 | 16 | |||

| F2(Superfine) | 95 | 13 | |||

| HPT800 | C1(Extra coarse) | 350 | 38 | 310-1200 | 630 |

| C2(Coarse) | 299 | 32 | |||

| M(medium) | 265 | 25 | |||

| F1(Fine) | 220 | 16 | |||

| F2(Superfine) | 150 | 13 |

Use Wufoo integrations and get your data to your favorite apps.