Project Description

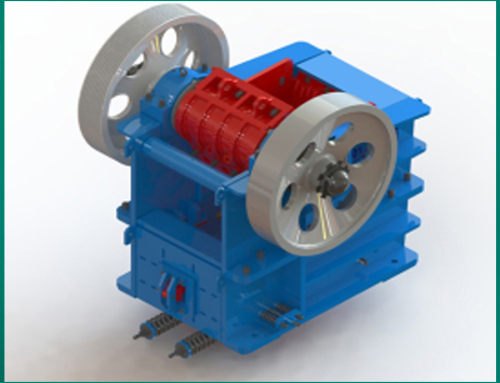

- The movable jaw adopts high quality welding technology, and the eccentric shaft is elaborate;

- Integral cast steel structure is adopted for bearing seat to ensure the complete matching with the frame;

- larger and more wearable main bearing is used to lengthen the service life;

- A newly designed tooth shaped cheek plate makes the available area of jaw plate longer and enhances the capacity

| Model | Opening Size(mm) | Max.Feeding Size(mm) | Discharge Opening Range(mm) | Shaft Speed(rpm) | Capacity(t/h) | Motor | Dimension(mm) | ||

| Model | Power(kw) | Speed(rpm) | |||||||

| JCE1302 | 180×1300 | 150 | 10-30 | 320 | 12-35 | Y225M-6 | 30 | 980 | 1320×2150×1175 |

| JCE1003 | 250×1000 | 220 | 20-40 | 330 | 15-50 | Y225M-6 | 30 | 980 | 1400×1850×1310 |

| JCE1303 | 250×1300 | 220 | 70-100 | 290 | 26-85 | Y250M-6/ Y280S-6 | 37/45 | 980 | 1450×2150×1175 |

| JCE604 | 400×600 | 350 | 35-85 | 250 | 15-70 | Y225M-6 | 37/45 | 980 | 1920×1460×1840 |

| JCE800×1060 | 800×1060 | 650 | 80-160 | 275 | 125-350 | Y315L1-6 | 110 | 990 | 2923×2294×2865 |

| JCE860×1100 | 860×1100 | 720 | 100-225 | 240 | 200-500 | Y315L1-6 | 132 | 985 | 3300×2320×3120 |